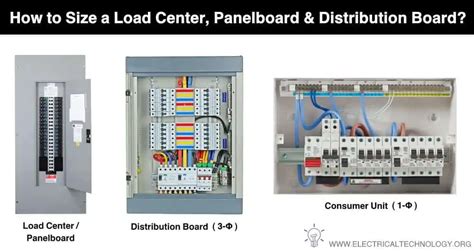

distribution box size In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples. Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

0 · types of distribution box

1 · electrical distribution panel sizes

2 · electrical distribution box types

3 · electrical distribution box sizes

4 · distribution box dimensions

5 · distribution board size chart

6 · db box size chart

7 · 3 phase distribution board sizes

Product is Ready to Operate out of the Box, Including Four Rear Mounting Holes, Mounting Feet, Wall Anchors, Hardware, and Wire Ties to Simplify Installation. Count on Zoeller® Pumps to deliver the very best solutions as the leading brand for pumps and pump accessories.

8-Hole Distribution Box with Dosing Mid-wall (1 Inlet/ 7 Outlet, 28" x 15" x 14") (8DB-BAF) When conductors come into a junction box in one raceway and exit the box in another raceway (not a straight pull) of a different size, how much distance do you need between those raceways? You need six times the trade .

8-Hole Distribution Box with Dosing Mid-wall (1 Inlet/ 7 Outlet, 28" x 15" x 14") (8DB-BAF)In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples. When conductors come into a junction box in one raceway and exit the box in another raceway (not a straight pull) of a different size, how much distance do you need between those raceways? You need six times the trade size of the larger raceway. According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula: \footnotesize L_\text {min} \geq 8 \times t_\text {max} Lmin ≥ 8 × tmax. where:

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

ABB Mini Center Compact distribution boards are the basis for development and growth in meeting all the demands for a successful future in residential, commercial, and infrastructure segments.

Contractors don't want to insecurity, and the trust they put in AJ Foss speaks volumns. A quality family-run operation that has served southern NH for decades. Choosing the right size box for your wiring project is essential for safety and efficiency reasons. By following these simple steps based on NEC guidelines, you can ensure that your wiring project meets code requirements and avoids potential hazards.American Distribution Boxes are made of high-density polyethylene for years of dependable use. They are non-corrosive, strong, and lightweight for easy handling. Inlet and outlet elevations are positioned to provide equal distribution and meet most local codes.

By considering the number of circuits, breaker size, future needs, space constraints and local codes, you can choose the right size distribution box. Remember, consulting a qualified electrician is key to selecting and installing the most suitable box for .8-Hole Distribution Box with Dosing Mid-wall (1 Inlet/ 7 Outlet, 28" x 15" x 14") (8DB-BAF)

In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples.

When conductors come into a junction box in one raceway and exit the box in another raceway (not a straight pull) of a different size, how much distance do you need between those raceways? You need six times the trade size of the larger raceway. According to the 2020 NEC®, our box should have a size of at least eight times the largest conduit when considering straight pulls. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula: \footnotesize L_\text {min} \geq 8 \times t_\text {max} Lmin ≥ 8 × tmax. where:

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.ABB Mini Center Compact distribution boards are the basis for development and growth in meeting all the demands for a successful future in residential, commercial, and infrastructure segments.

Contractors don't want to insecurity, and the trust they put in AJ Foss speaks volumns. A quality family-run operation that has served southern NH for decades. Choosing the right size box for your wiring project is essential for safety and efficiency reasons. By following these simple steps based on NEC guidelines, you can ensure that your wiring project meets code requirements and avoids potential hazards.

types of distribution box

American Distribution Boxes are made of high-density polyethylene for years of dependable use. They are non-corrosive, strong, and lightweight for easy handling. Inlet and outlet elevations are positioned to provide equal distribution and meet most local codes.

thermal insulated bento stainless steel food container lunch box

thermocouple junction boxes

While for the wire, the AWS E70 wire in S-2, S-3, and S-6 care ideal for welding on mild steel, but for aluminum, you should use ER4043 and ER5356. For stainless steel, you can go for ER308 and ER308L.

distribution box size|3 phase distribution board sizes